Your One-Stop Solution for Complete Aluminum Profile Extrusion Line

Aluminum Extrusion Equipment

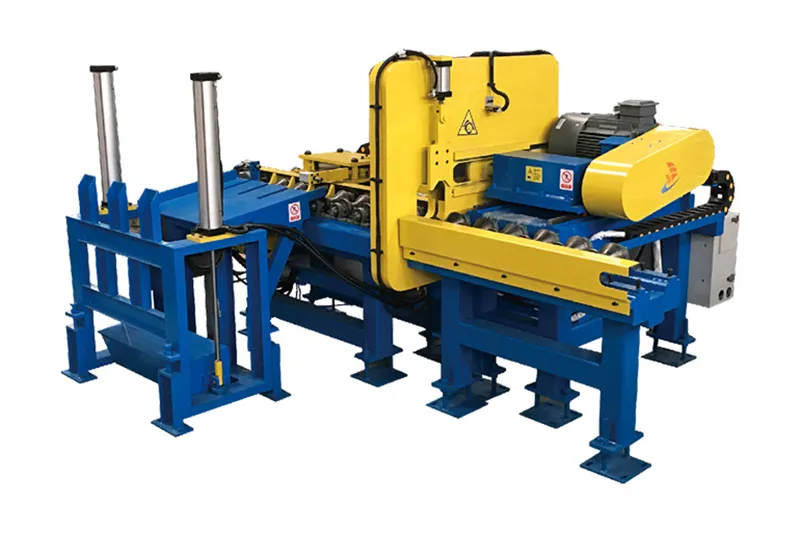

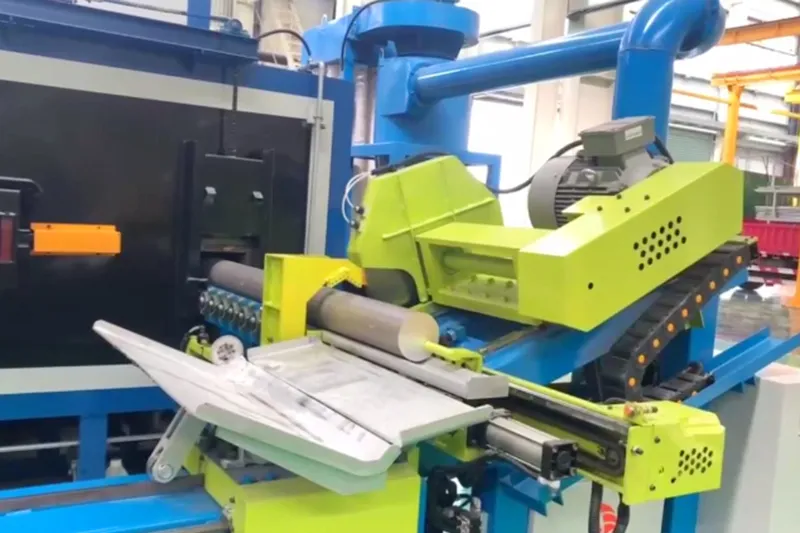

Hot Shear

Aluminum billet saw for cutting heated billets before entering extrusion press

Aluminum Extrusion Equipment

Hot Shear

Aluminum billet shear for cutting heated billets before entering extrusion press

The hot shear acts as a connecting device between the aluminum billet heating furnace and the extrusion press. It is a widely used auxiliary component in aluminum extrusion production lines. Designed for accurate length cutting and smooth cross-section finishes, this hot shear optimizes billet utilization and improves aluminum profile production efficiency.

The hot shear machine is mainly composed of five components: conveying roller bed, sliding type hot shear, aluminum scrap recycling unit, fixed length measuring table unit and billet turn-over feeding unit. The main function of the hot shear is to transfer the aluminum billet from the heating furnace to the hot shear roller bed, then cuts the billets to fixed lengths based on specifications. Finally, the aluminum billet is transferred to the extrusion press's mechanical hand after cutting.

| Max. Cutting Diameter | 500mm |

| Min. Cutting Diameter | 90mm |

| Shear Blade Diameter | 905-1100mm |

| Shear Blade Thickness | 2-5mm |

| Number of Saw Teeth | 60-1000 teeth |

| Rotation Speed | 1500-3000rpm |

| Feed Rate | 50 -500mm/min |

| Shear Blade Motor Power | 3-15kW |

| Feed Motor Power | 0.5-2kW |

| Clamping Force | 1-10kN |

| Clamping Range | 90-500mm |

| Machine Dimensions | Length:1500-3000mm Width:800-1500mm Height:1200-2000mm |

| Machine Weight | 1000-5000kg |

- Achieves a pulling speed of over 1.2 meters/second, compared to the conventional speed of under 1 meter/second.

- Seamless cutting at billet joints, with an intelligent saw control system that automatically adjusts the saw speed based on the aluminum extrusion speed results in higher yield rates.

- Crescent-shaped clamps ensure smooth pulling and cutting, preventing deformation and eliminating vibration marks on the aluminum profile surface.

- Powered by Siemens servo motors, utilizing servo motor encoder positioning technology, eliminating traditional proximity switches and sensors to reduce fault rates and enhance stability.

- All structural joints use gear and rack drives, offering long service life and zero-fault operation.

- Enables remote control and maintenance for added convenience.

- The only system in the industry to utilize imported Siemens Wi-Fi communication technology.

- Tracks made with square tube supports, cold-drawn steel, and elevator rails ensure precision and durability. Gear hardness is rated at 45°, and rack hardness at 40°.

- Automated sampling at the initial, middle, and final stages of pulling, with the system completing the sampling process autonomously.

- Uses imported SKF and NSK bearings for reliability and longevity.